1. Introduction

– This material brings the main recommendations of the manufacturer and/or described in the standard for the correct execution of the laying of Ceramic Coatings on the wall, seeking:

– Decrease material losses (ceramics, mortar, etc.);

– Improve quality and efficiency of the workforce;

– Enhance the desired aesthetic effect (improving alignment, arrangement of pieces, less cutting, etc.);

– Ensure technical performance required by standard (adherence, useful life, etc.);

– Avoid future problems (slipping, damp stains, cracks, etc.);

2. Important Preliminary Tips:

– Qualified labor: Before hiring a professional tile maker, make sure that he/she has good experience in laying ceramic tiles. If possible, look for indications, references, request photos and evaluate previous work of the professional to be hired, thus seeking to certify whether the quality of the labor offered meets the expectations for the work you want to carry out.

Important: Incepa is not responsible for damage caused to the product(s) resulting from incorrect handling or labor failures, which occurred in the application process.

– Appropriate Tools: Attention! The lack of specific tools or accessories, worn or in poor condition, are strong indicators of possible problems in the laying phase, such as excessive breaks generated when trying to make cuts, (worn or poor quality discs and vines), cuts with imperfect finishes (crooked, serrated, etc.), irregular settlement with misaligned and/or out of level parts (lack of proper spacers and levelers), among other problems generated by the non-use of appropriate machines, tools and accessories that enhance the quality of settlement.

– Recommended Machines, Tools and Accessories:

– Adhesive mortar:

– For wall coverings, Roca Cerâmica recommends ACI type mortar. If you want to apply another type of ceramic product on the wall (floor or porcelain), it is essential to use the mortar recommended by the manufacturer and strictly follow the instructions regarding preparation and use. Below indicative table of mortar for each type of product Roca Cerâmica:

| Product typology |

Recommended mortar type |

| – Ceramic coatings for indoor use |

ACI type mortar |

| – Pure stoneware floor |

ACII type mortar |

| – Technical and enameled porcelain tiles |

ACIII type mortar, Floor on floor, Specific for porcelain |

Comments:

– For application in front of barbecue grills, fireplaces, on other ceramics, or in specific situations, consult the mortar manufacturer.

– According to the NBR-ABNT standard, 13754 pieces with an area equal to or greater than 900cm2 must be applied with double gluing of mortar (mortar on the back of the piece and on the base to be laid), more details will be seen ahead in step by step for laying ceramic coverings.

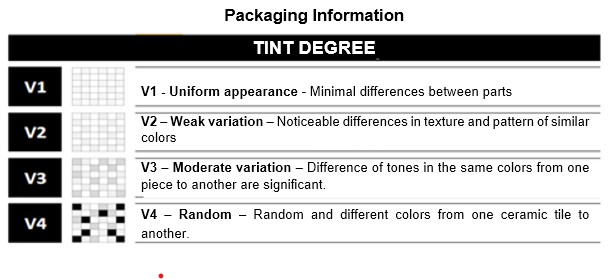

– Inspecting and Knowing the Product: Before starting the application, make sure that the product to be laid is recommended for the intended location, if the quantity purchased easily meets the area to be coated (counting % for losses and cutouts, more parts for future maintenance) and if the product boxes are of the same reference, shade, caliber, etc. It is also essential to read the guidelines printed on the packaging by the manufacturer, these report regulatory requirements and specific characteristics of the product to be applied that directly influence the correct form of its settlement, such as minimum joint, maximum lashing allowed, arrow direction, etc.

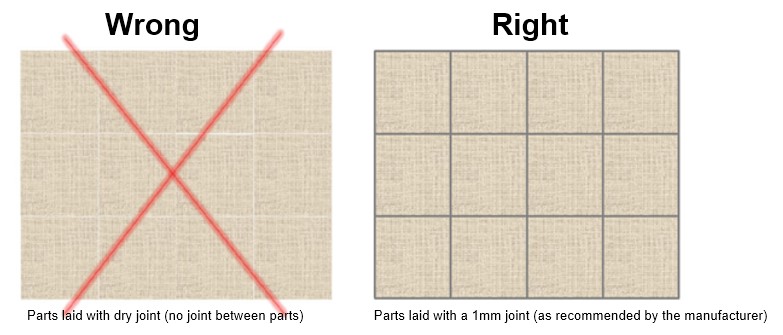

– Example: For rectified products and flat edge, the minimum joint recommended by Incepa is 1mm between the pieces.

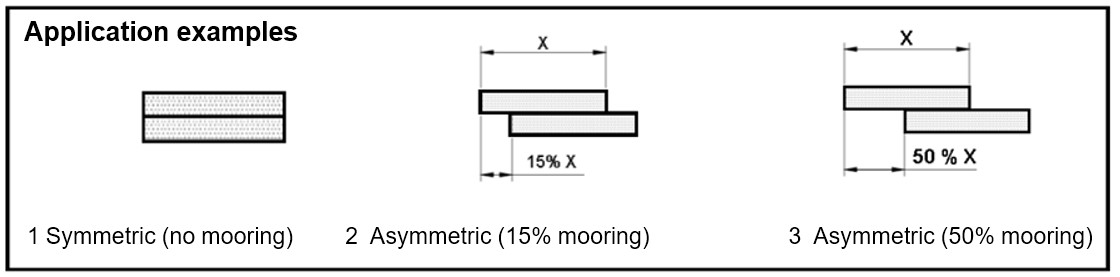

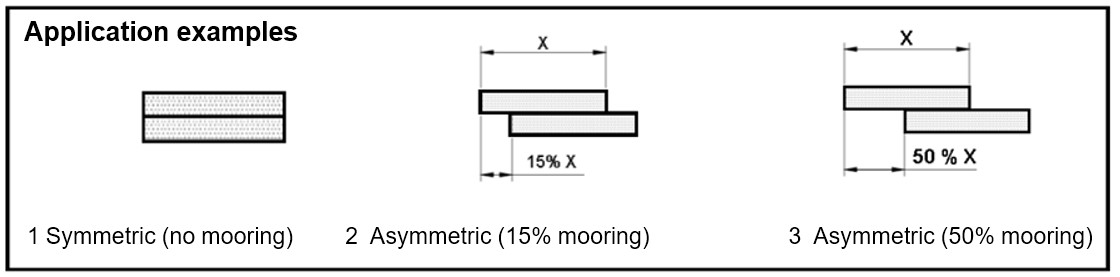

– Example 2: Types of application and maximum percentages allowed (with and without the use of Leveling spacers)

Application types:

Maximum permissible mooring percentages according to application:

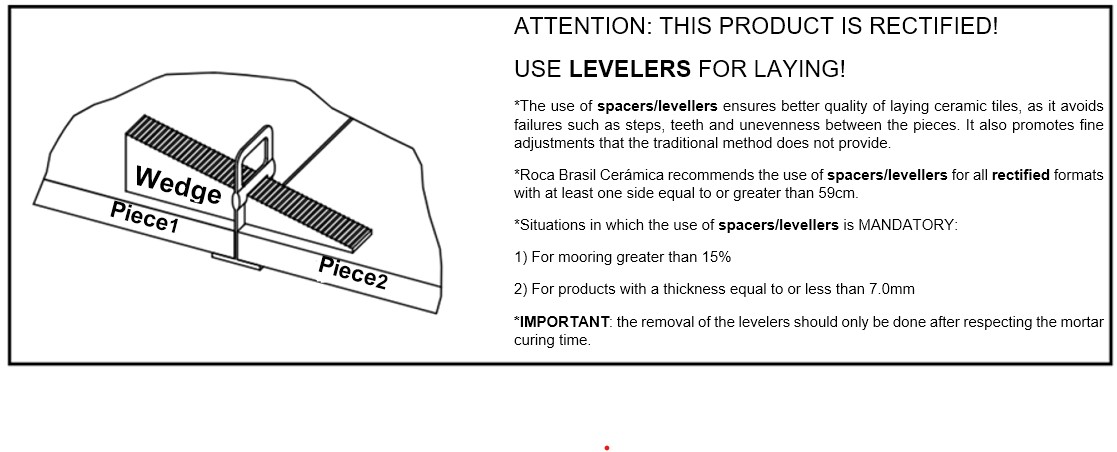

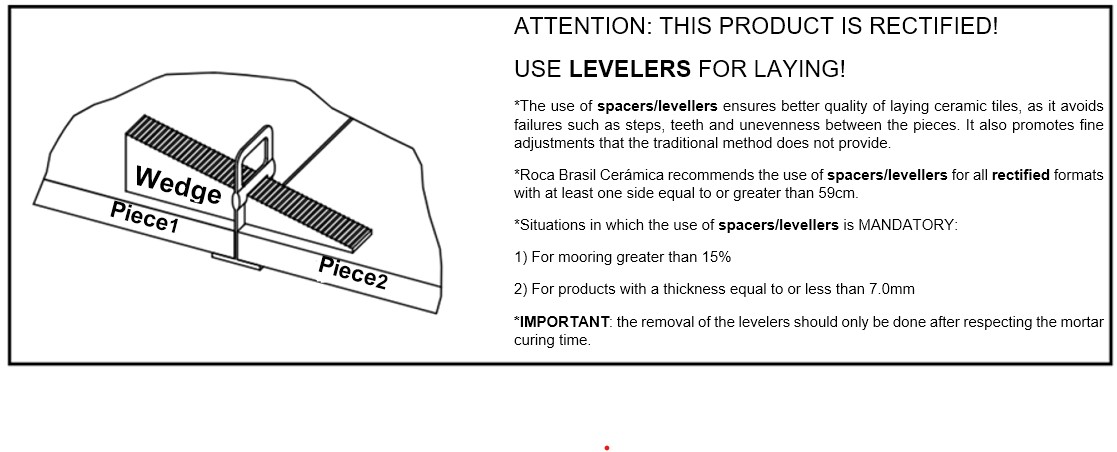

– Mismatched application without the use of leveling spacers (Wedge) the maximum lashing allowed is up to 15%;

– Mismatched application with the use of leveling spacers (Wedge) the maximum lashing is up to 50%;

Heads up:

– Roca Brasil Cerámica is not responsible for laying errors resulting from failure to follow the guidelines recommended by the manufacturer and/or required by standard.

– The wedge leveler spacer is mandatory for mismatched applications whose lashing is greater than 15%, if not used, the product will inevitably present unevenness from the retraction of the mortar and curvature of the pieces

– Settlement Base Verification

– The bedding base must comply with the ABNT-NBR13754 standard “Covering of internal walls with ceramic plates and using adhesive mortar”, below are some of the main recommendations:

– The baseplate must consist of one of these options: concrete cast in loco or precast, coated or not with roughcast and plaster; Masonry made of solid bricks or ceramic blocks coated with roughcast and plaster; Masonry of hollow concrete blocks, cellular concrete blocks or sand-lime bricks, coated or not with roughcast and plaster.

– When the base is coated with plaster, make sure that the plaster is well adhered to the base and does not present a hollow sound;

– The wall must be aligned in all directions, so that the same plane is obtained in its entirety;

– The surface that will receive the mortar must be clean, free from loose particles, oils, etc., which could compromise the adhesion of the adhesive mortar;

– The deviation from the flatness of the surface to be applied must not be greater than 3mm in relation to a straight ruler with 2m in length;

– It must have been executed at least 14 days in advance of plaster curing and at least 7 days for other surfaces, thus seeking to reduce the effect of mortar retraction on the ceramic coating to be executed.

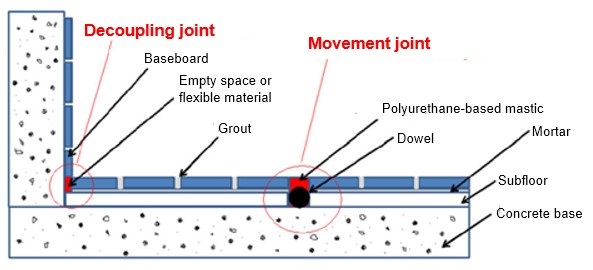

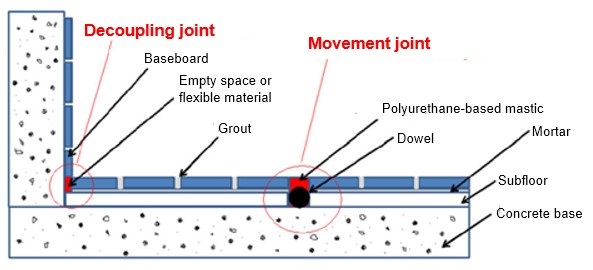

– Movement and Decoupling Joints:

– The movement joint must be performed on walls with an area equal to or greater than 32m2, or when one of the sides is greater than 8 meters.

– In places exposed to moisture, the movement joint must be carried out on walls with an area equal to or greater than 24m2 or when one of the sides is greater than 6 meters.

– In the perimeter of the coated area, at the meeting of the area covered with floors and ceilings, columns, beams or with other types of coverings, and where there is a change in the materials that make up the wall, it is recommended to design and carry out desolidarization joints.

Step by Step for Laying Ceramic Tiles

– Start Settlement Only After Completing the Steps Below

– Water and sewage pipes duly built in and tested for tightness;

– Conduits, light board, junction box duly built in and tested;

– Fixing the frames and stops;

– Ceiling coatings;

– Verification of the Application Surface of Ceramic Coatings

– The baseplate must comply with the ABNT-NBR13754 standard “Covering of internal walls with ceramic plates and using adhesive mortar”, for further details, see preliminary tips and/or the standard itself;

– Check! The seating surface must be flat and aligned in all directions.;

– When the baseplate is coated with plaster, confirm its adherence before application, tapping with a piece of wood, if a hollow sound is identified, the plaster needs to be removed and redone;

– With the aid of a spatula, remove lumps of cement, mortar, plaster remains, paints, glue, among other materials adhered to the surface that may affect the adherence and leveling of the pieces;

– Then, with a brush or broom, sweep the surface to be applied, which must be clean and free from dust and/or loose particles (sand, mortar, plaster residues, spackle, etc.) that could compromise the mortar adhesion;

– Before laying, it is important to moisten the surface to be laid with the aid of a brush plus a bucket of water (without saturating). This operation prepares the surface for receiving the mortar and enhances the adhesion of the mortar to the substrate (base).

– Mortar

– According to preliminary tips, the mortar recommended for laying ceramic tiles is the ACI type.

– Preparation: Place the measure of water indicated on the package by the manufacturer in a bucket and under agitation of the mixer, add the powdered compound to the mortar until its end, keep stirring until obtaining a homogeneous mixture, without lumps, pasty and adherent. For the mortar additives to start their action, it is necessary to leave the mixture resting for a period indicated by the manufacturer (check the packaging, on average 15 minutes, depending on the manufacturer), then shake again and that’s it, the mortar is ready for use. Note: Never add more water than recommended by the manufacturer.

– Usage time: After preparation, use the mortar within 2 hours and 30 minutes, with the addition of water and other products being prohibited.

– Type of gluing (single or double layer of mortar), trowel and medium consumption.

Attention!

The way of laying, troweling and mortar consumption varies according to the size of the ceramic piece to be laid. According to NBR-ABNT 13754, pieces with an area equal to or greater than 900cm2 (30cmx30cm) must be applied with a double layer of mortar (mortar on the back of the piece and on the base to be laid). On the other hand, pieces with an area smaller than 900cm2 must be applied with a single layer of mortar (mortar only on the base to be laid). Below indicative table for trowel, procedure to be carried out and approximate average consumption based on the area of the piece to be applied:

Trowel and gluing table by format

| S surface area of ceramic plates (cm2) |

S surface area of ceramic plates (cm2) |

S surface area of ceramic plates (cm2) |

S surface area of ceramic plates (cm2) |

| S < 400 |

6x6x6 squares |

Simple glue |

± 4,0kg/m2 |

| 400 ≤ S < 900 |

8x8x8 squares |

Simple glue |

± 4,5kg/m2 |

| S ≥ 900 |

8x8x8 squares |

Simple glue |

± 7,5kg/m2 |

Planning:

– The first step is to identify the size of the piece to be applied, and then determine the trowel and the gluing process to be carried out (single gluing or double gluing).

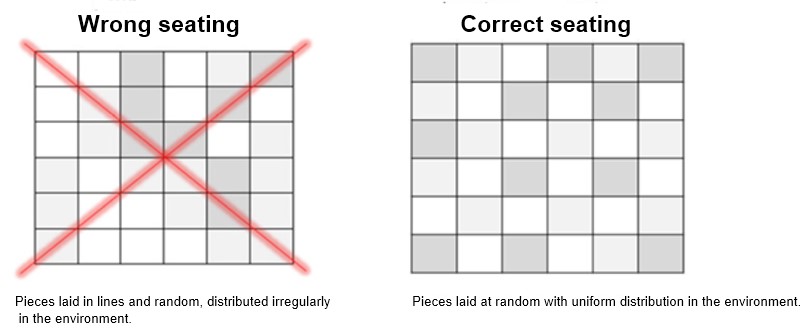

– Later, review the arrangement of the pieces: Before starting the collage, it is recommended to review the layout, making sure that the layout of the pieces chosen is the one that best values the product and the environment, simulating and preventing unforeseen events, avoiding excessive clipping. , respect the movement and desolidarization joints, meet the desired aesthetic effect, etc.

– Double Gluing Process Execution: (pieces with an area greater than 900cm2)

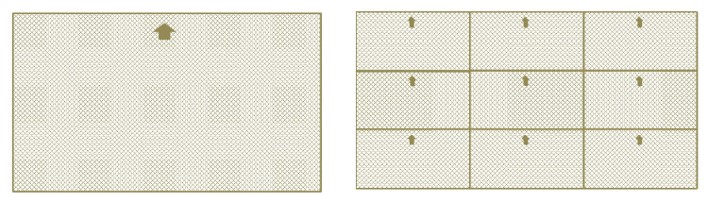

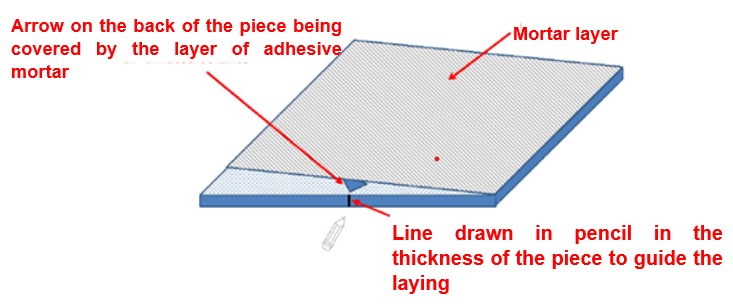

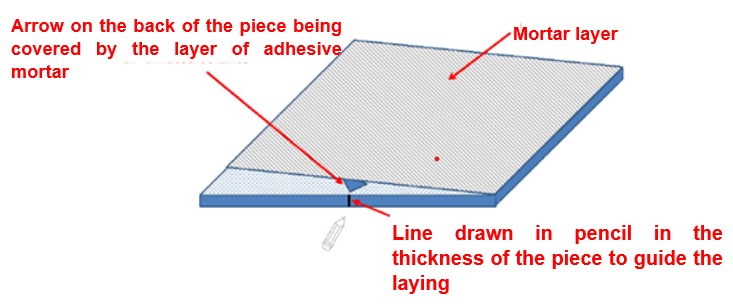

– Identifying the Application Targeting Arrow:

– Remove the piece from the packaging and identify the orienting arrow on the back of the piece (back). This arrow serves to direct the laying, that is, all the pieces must be applied on the wall pointing in a single direction.

Note:

The problem is that with the application of mortar on the back, the arrow is covered, thus generating margins for application failures. To prevent this from happening, Incepa recommends using a pencil to scratch the side of the piece that contains the arrow (thickness). In this way, even after applying the mortar and covering the arrow, it is possible to identify the correct side for application through the lateral marking.

– Applying the mortar on the back of the piece and base to be laid (Wall):

– Before applying the mortar, make sure that the back (back of the piece) is free of dust or loose particles that could compromise the adhesion of the pieces, if necessary, clean the back with a plastic bristle brush before application.

– Rearward, with the smooth side of the steel trowel (see trowel to be used in the trowel table and gluing by format) spread the mortar on the back of the piece and on the base to be laid, pressing and dragging the trowel against the surface to be applied, thus forming a uniform mortar layer between 3mm to 4mm thick.

– Then, with the serrated side of the trowel (at a 60º angle in relation to the base to facilitate the operation), form grooves (cords) in the mortar applied on the back of the piece and on the base to be laid (wall). These cords will facilitate the leveling, alignment and fixation of the ceramic tiles.

– The excess of mortar removed with the trowel must be returned to the mortar container to be used in the next piece.

Note:

– To prevent excess mortar from migrating to the surface of the piece during placement and densification, with a trowel (at a 45º angle in relation to the base to facilitate the operation) remove the excess mortar applied to the sides of the piece, forming kind of a bevel.

– According to NBR 13754-1996, it is mandatory to use a double layer of mortar (mortar on the back of the piece and base to be laid) for laying formats larger than 900cm2 (30x30cm). Failure to comply compromises the adherence of the parts and automatically invalidates the warranty.

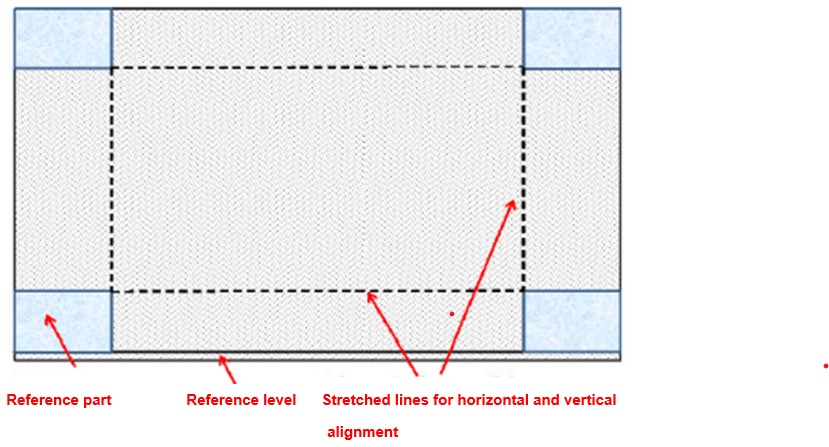

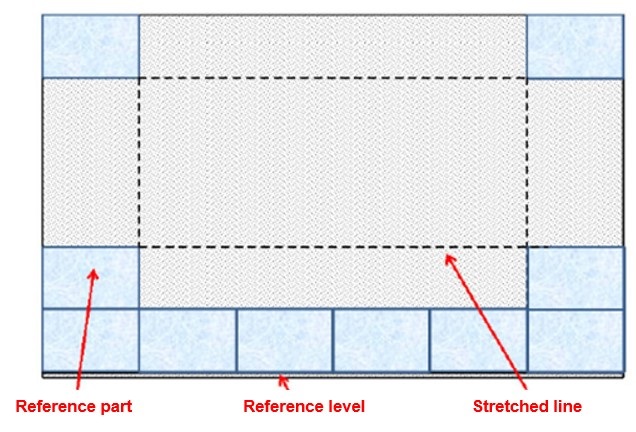

– Laying the Pieces:

– The laying of the pieces must be carried out from the bottom up, one piece at a time;

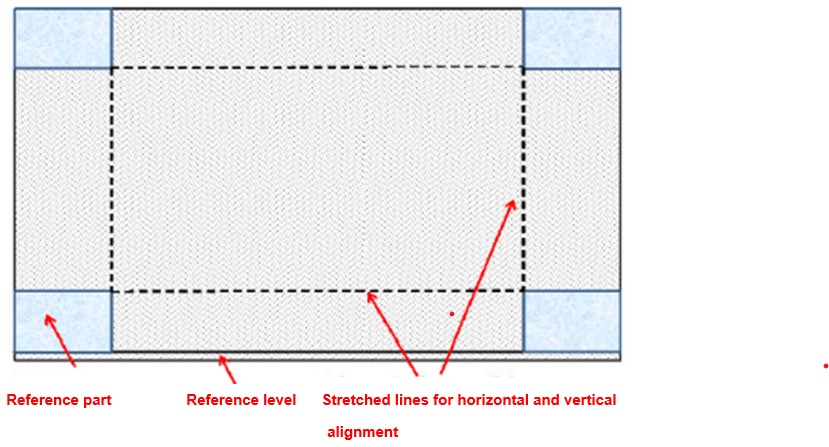

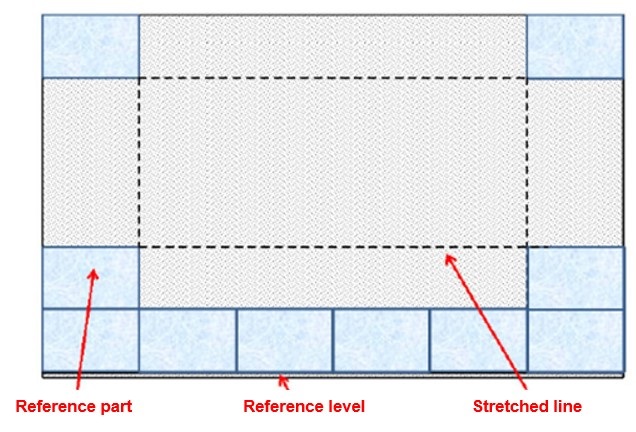

– At the ends of the base of the wall to be laid, install 2 pieces that will serve as guide pieces (one at each end of the wall), leveling them (taking as a base and reference floor level) and fitting them properly so as not to leave the position. Afterwards, stretch the line at the upper end of the applied pieces, thus facilitating the application and alignment of the other pieces of this first row.

– To ensure the plumb of the vertical rows, it is also recommended to apply guide pieces (leveled and upright) at the upper ends of the wall to be laid, and also to stretch the line between these pieces, referring to the ends of the pieces.

– Once the guide parts are installed and the reference lines stretched, the sequence in the laying of the other parts until the first row is closed, remembering that the minimum spacing recommended by the manufacturer must be respected. Note: To (use appropriate spacers).

– Important to emphasize that the pieces must be applied with a double layer of mortar and with the arrows directed in a single direction, thus guiding the application, thus ensuring better adherence, alignment, marriage of the pieces, etc.

– For application of the parts, it is recommended to place them slightly out of position (around 5cm) and with a rubber hammer (preferably white) perform small knocks and vibrations, so that the air draw and total crushing of the cords occur, in addition of adjustments in terms of level and plumb, as well as moving the pieces to the final position.

– Once the first row has been closed, repeat the installation operation of guide pieces at the ends, reference line, laying of the central pieces, etc., in the upper row and so on until the end of the wall where the installation takes place.

Comentarios:

– Es fundamental que las piezas guía se apliquen en la posición correcta, dentro del nivel, plomada, escuadra, etc. Para ello utilizar todos los recursos disponibles (línea, nivel de burbuja, nivel de manguera, nivel de ocio, regla de aluminio, etc.) asegurando así el correcto asentamiento de estas piezas, que serán referencias para la colocación del resto de piezas en fila y columna.

– Las piezas deben ser aplicadas de forma que garantice al menos el 70% de aplastamiento de los cordones, a comprobar, realizar una prueba de puesta en marcha al inicio y durante el tendido, y si no se ha alcanzado este porcentaje mínimo realizar ajustes ( intensificando golpes y vibraciones) hasta alcanzar este porcentaje. También es importante realizar una prueba de percusión dando golpecitos con el dedo, si se identifica un sonido hueco, se debe retirar la pieza y volver a colocarla (falta el mortero).

– Para el asentamiento de grandes formatos y revestimientos rectificados, Incepa recomienda aplicarlos con ayuda de espaciadores niveladores tipo cuña. Para mayor información consultar al Departamento de Asistencia Técnica de Incepa.

Importante:

No olvide realizar el movimiento y desolidarización de las articulaciones según lo recomendado por ABNT 13754: 1996 e informado en los Consejos Preliminares Importantes.

Cortés:

– Son necesarios para realizar paginación, cerramiento de ambientes, para contornear elementos estructurales como pilares y vigas, empotrar elementos de iluminación, desagües, tuberías, crear juntas de movimiento y dilatación, entre otros.

– Un corte perfecto solo es posible con la combinación de herramientas de calidad y en buen estado, operadas por mano de obra calificada.

– Los cortes rectos deben realizarse con el cortador de cerámica de sobremesa (videa).

– Con el cortador de cerámica de mesa, los principales consejos son:

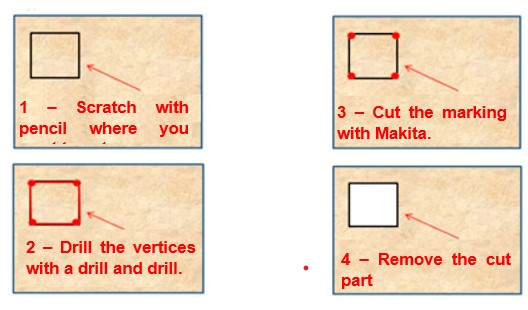

– Raspa la pieza con un lápiz donde quieras cortar;

– Coloque la pieza en el cortador de cerámica y asegúrese de que esté bien apoyada y marcada debajo del video cortado;

– Pasar la enredadera de diamante sobre la marca con fuerza media (si se fuerza demasiado dará la apariencia de estrías, comprometiendo la calidad del corte).

– Una vez rayado el esmalte, colocar la pieza sobre el separador cortador de cerámica y utilizar la palanca con la fuerza hasta el desprendimiento y separación de las partes;

– Si es necesario, con una lija de hierro apoyada sobre un trozo de madera, lijar ligeramente la superficie rayada, dando el toque final al acabado. (Si el acabado está bien, elimine este paso).

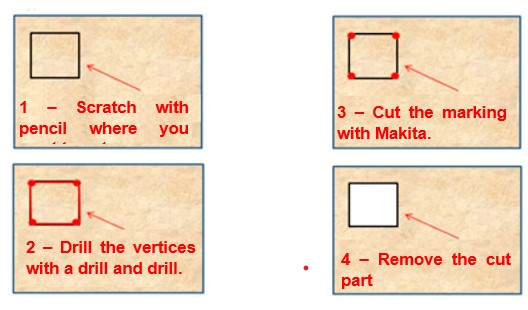

– Los cortes irregulares para la inserción de cajas de paso, contornos de columnas o vigas, etc., deben realizarse con la cortadora manual (makita), los principales consejos se encuentran a continuación:

– Raspa la pieza donde quieras cortar;

– Taladrar con taladro en los vértices de los cortes, buscando aliviar tensiones;

– Realizar el corte con la cortadora manual;

– Resalte la parte que no se utilizará;

– Lijado con papel de lija de hierro apoyado sobre un trozo de madera para un mejor acabado;

– Circular cuts for insertion of pipes, lights, etc., must be carried out with the aid of a ceramic cup saw, the main tips are:

– Measure the size of the diameter of the pipe, light, drain or other element that you want to embed in the part;

– With the help of (drill + hole saw for ceramics in the correct diameter) make the desired cut;

Rejoining:

– Use flexible grout, in the preferred color, or another one as recommended by the manufacturer;

– Prepare as indicated and recommended by the grout manufacturer;

– Rejoin at least 3 days after laying;

– Clean the joints, leaving them free from any type of dirt that could impair the penetration and adhesion of the grout;

– Wet the joints with the aid of a brush (do not saturate), this will prepare the joints for better adhesion of the grout, it will also facilitate the hydration and the grouting process;

– With the joints still damp, apply the grout in excess with the aid of a spatula or rubber trowel, completely filling the joints.

Note:

To facilitate the application, perform diagonal movements in relation to the joints.

Note:

Carry out the procedure with medium strength and caution, seeking not to damage the product.

– Leave to dry for 15 minutes, then remove excess grout and clean the coating with the aid of a damp sponge, then dry with a clean cloth.